- Home

- Case

- Cable Tray Roll Forming Machine

- Color Steel Roof Sheet Roll Forming Machine

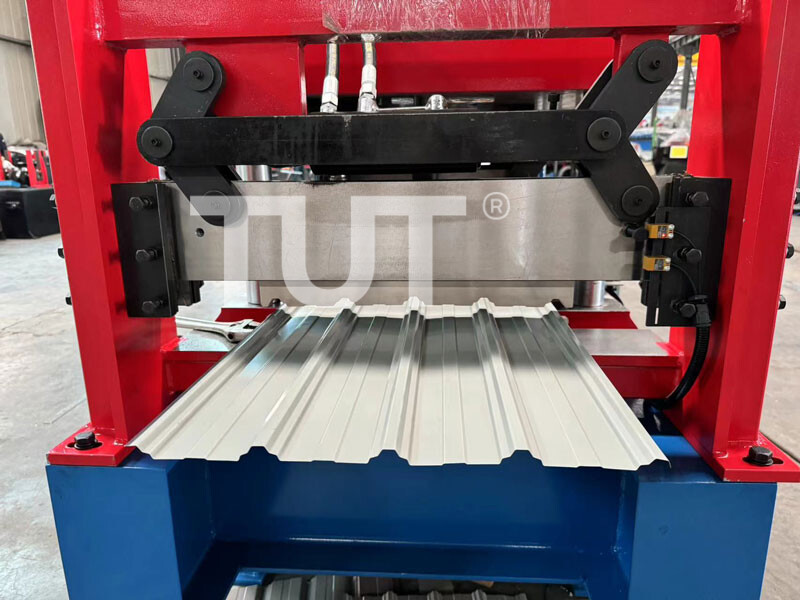

Color Steel Roof Sheet Roll Forming Machine

Introduction

Color steel roof sheet roll forming machine is designed with 3 groups of hydraulic punch stations, the whole roof sheet roll forming machine is composed of decoiler, main roll forming machine, hydraulic punch, cutting device, outer table, control box, etc. We can also produce different types of roof sheet roll forming machines, such as corrugated sheets roof roll forming machine, double layer roof sheet roll forming machine, standing seam panels roll forming machine, and various other profiles used in residential, commercial, and industrial roofing projects. They are widely used in the construction industry due to their efficiency, accuracy, and ability to produce large quantities of roofing material in a relatively short amount of time.

Working Process

Decoiling- Feeding Guide – Main Roll Forming- Hydraulic Punch- Cut to Length- Outer table

Technica Parameters

• Material thickness: 0.5-0.8mm

• Tensile strength: 550 Mpa

• Roller stations: about 15 stations

• Forming speed: 0-15m/min.

• Main shaft diameter: ¢75mm, material 45# steel

• Roller material: #45 steel , chrome coated thickness≤05mm.

• Roller machining process: #45 steel– turning — CNC machining–chrome coated

• Main motor power: 15KW

• Hydraulic cutting power: 3Kw

• Cutting blade material: Cr12Mov, HRC:56-58°