- Home

- Case

- Purlin Roll Forming Machine

- CZ purlin roll forming machine

- CZ Purlin Roll Forming Machine

CZ Purlin Roll Forming Machine

- General Details

- Related Products

CZ Purlin Roll Forming Machine

Introdcution

C Z Purlin Roll Forming Machine is used to produce C Purlin and Z Purlins with very less changeover time that the exchange time is only 1 minute.

TUT new technology designed C Z Purlin Roll Forming Machine can roll forming C and Z shape purlins with width range from 80-350mm, thickness up to 5mm.

Our C and Z Purlin Roll Forming Machine can produce both C and U Purlin without any change of the rollers. The entry guides and the straighteners are attached to the mill stands. Therefore changing the product dimensions is very simple and quick. Some of these mills are equipped with servo motors and PLC controllers or computers.

The whole line is containing prepunching and precutting presses can produce infinite kinds of “C” channels (studs) and “U” channels (tracks) within the parameter of the machine without tool change. The only requirement is to enter the part number (or dimensions)and the required quantities into the PLC or Computer system by Touch Screen . The product dimension changeover time can be as low as 1 to 2 min.

Technical Parameters

1. 3 Ton Manual Decoiler

- coil inside diamter: ø508±30mm

- Coil outside diameter: ø1800mm

- Coil capacity: 5Tons

3 ton manual decoiler for CZ purlin roll forming machine

2. Feeding & Leveling

- guiding roller material: Cr12,HRC58-62°

- 5 rollers leveling, 2 rollers up and 3 rollers down

feeding and leveling

3. Hydraulic Punch

- Total 3 sets punch moulds, with punch mould material Cr12Mov

hydraulic punch

4. Hydraulic Cutting

- cutting width≤500mm, cutting thickness≤0mm

- Cutting blade material: Cr12, HRC58-62°

cutting part for CZ purlin roll forming machine

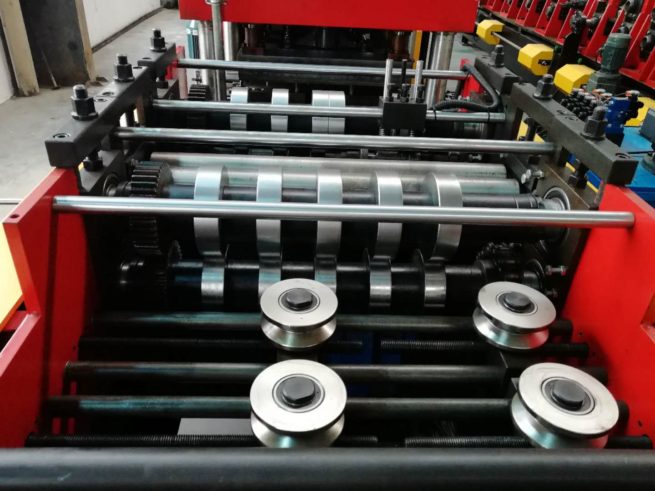

5. Main Roll Forming Part

- Roller material: GCr15, HRC58-62°, chrome coated.

- Shaft material: 40Cr, diameter 80mm, HB250-280°

- Spacer material: 45# steel

- Main motor power: 15Kw

- Dimension changed by guide rail with speed reducers by hand wheel manually. Thickness can be adjusted manually.

- Sliding Parts including speed reducer, coupling, transmission shaft, bevel gear transmission, high strength screw, guide rail, etc.

- Bearing: Harbin bearing, type 6213Z\6212Z, etc.

CZ purlin roll forming machine

6. PLC Control Box

- PLC brand: Panasonic, Japan

- Touch Screen: Beijing MCGS

control box for CZ Purlin Roll Forming Machine

7. Hydraulic Station

- hydraulic motor power: 7.5Kw

hydraulic station for cz purlin roll forming machine

Advantage of Our CZ Purlin Roll Forming Machine

- Save labor cost with design that producing different purlin size without changing any rollers.

- Save cost by pre-cutting design do not require change cutting blades for different sizes

- Save material by infinite sizing (any size within production range can be produced)

- Optional Punch holes at any position of purlin web side and flange side

- Fast efficiency with changeover time between C purlin and Z purlin only short to one minute.